Conversion of automotive lighting to LED

Modernity and energy saving.

M-TECH Poland has always been associated as a leader in the automotive lighting industry, setting the latest trends. For some time now, products from the category of LED kits designed to convert traditional halogen lighting have been included in M-TECH's range of products. The LSAL, LSF, LSG and finally LSPRO NEXT GENERATION series have set and continue to set the direction of development in this product segment, being a source of inspiration for others. The most technologically advanced solutions and top-quality components such as branded and efficient diodes, compact dimensions and a cooling system such as FrontAir have contributed to the success of all the series introduced. Despite the problems the world has faced in recent years (2020-2022), most notably the COVID-19 pandemic, M-TECH continues to work on expanding its product range in many segments of the automotive lighting market through continuous product improvement.

Choosing the right LED kit is not at all as simple and obvious as it might at first appear. In order to choose a product that meets all our needs, it is first necessary to pay attention to several elements and answer some extremely important questions.

Light source...

The light source is an extremely important, if not the most important element we should pay attention to when purchasing an LED conversion kit for traditional car lighting. Thanks to continuous technological developments, virtually everything has changed in this regard.

Initially, the most popular LED components/chips available on the market at the time were used as the light source. Most often, manufacturers used first-generation COB or SMD chips in kits for converting traditional halogen lighting to LED, which started to become increasingly popular and thus also cheaper. With advances in technology and the ever-present quest for miniaturisation, the emerging LED light sources used in this type of solution became smaller and smaller on the one hand, and more and more efficient (number of lumens per 1W) on the other. Currently, the most popular solution in retrofits is the CSP1860 LEDs. Of course, this is no different in all the LED retrofit series available from M-TECH Poland, i.e. LSF, LSG, LSAL and LSPRONG.

Contrary to appearances, the topic of choosing the right LED is by no means an easy one, as higher flux from a smaller chip area increases the operating temperature of the chip itself. The remarkable luminous efficiency at such a small size as the CSP1860 diode was achieved thanks to the wire-free multi-point current distribution technology in a single chip, as well as the integration of 3 chips on a single substrate. This integration has resulted in the creation of a homogeneous rectangular light surface (with a shape and light distribution similar to that of a halogen filament) and not, as in the earlier generation where the light sources were LEDs spaced apart. The new design, results in more homogeneous light, better coupling with headlamps and lenses, and the absence of spots and shadows occurring on the street with multiple individual LED chips (multi-chip). In addition, a specially selected common substrate integrates thermal energy from and provides better heat dissipation. In addition, they have built-in inverters that form part of a double overheating control system.

Cooling system...

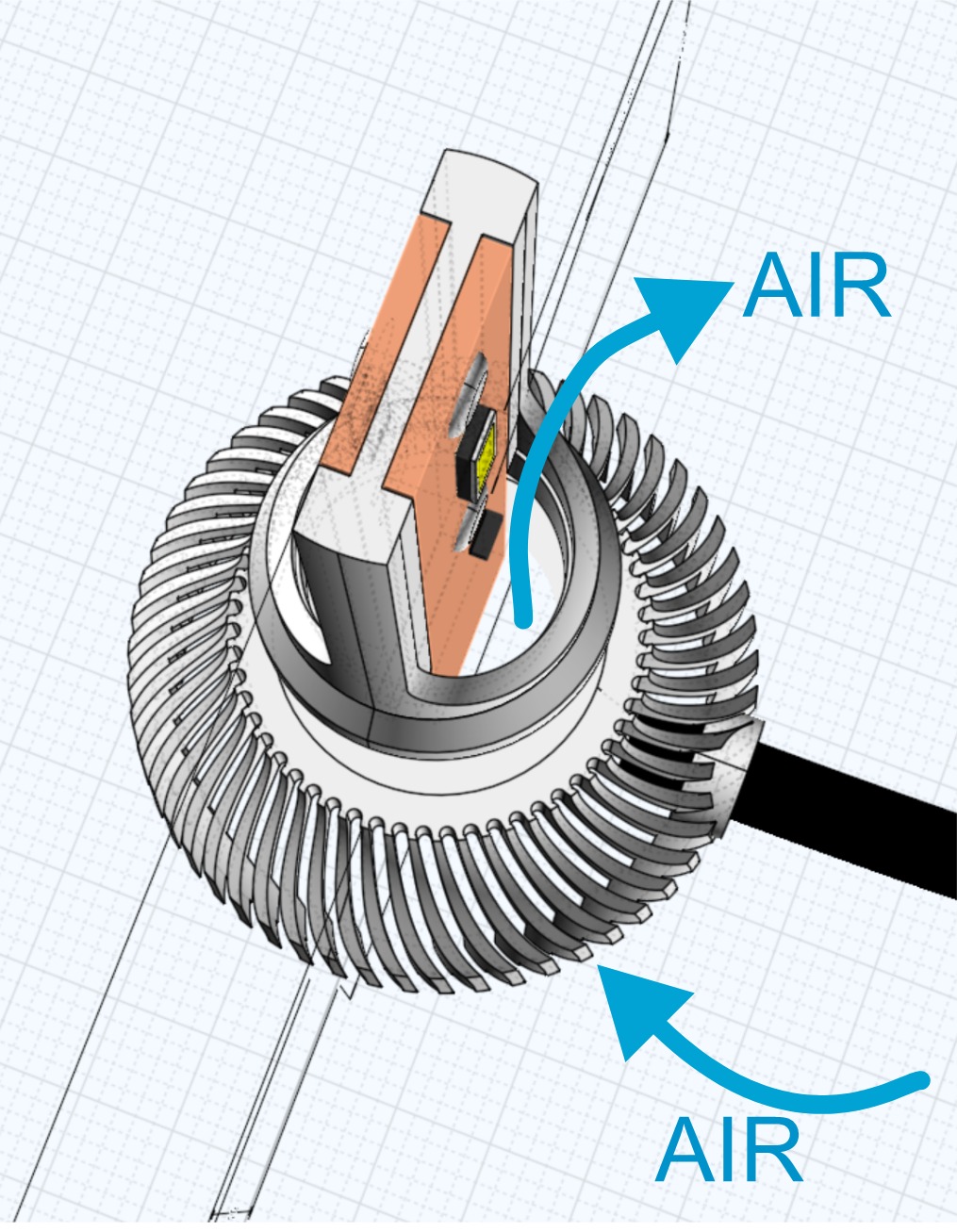

From the outset, the use of a suitably efficient cooling system in the LED set retrofit category products was quite a challenge. The first LED sets designed to convert traditional lighting were based on a passive cooling system. Its basis is a heat sink in the form of a ribbed element or special metal/aluminium strips, which are responsible for dissipating heat from the diode, protecting it from overheating and, consequently, from damage. Initially, I turned my attention to this type of solution, mainly because I was concerned that the use of active cooling based on a moving element such as a windmill would not work in a headlamp due to possible dust particles that could affect the operation of the windmill and, consequently, the retrofit itself. Reality, however, has verified the way we think about cooling systems. It has turned out that active cooling is much more efficient and, in addition, advancing technological developments and miniaturisation are an added advantage.

In the LSF, LSG and LSPRO next gen models, the cooling system is the only major advantage. The use of the innovative FrontAir technology (the cooled air is pushed out through the stem chamber), thanks to the special design of the "bulb" body, allows approx. 15-20% of the cooled air to be directed directly at the diode. This has a positive effect on the thermal stabilisation of the chip and also forces air circulation in the reflector chamber itself. This has a direct impact on the service life and thus on road safety.

Application of the NTC sensor

Over time, the market has started to force manufacturers to use more and more new solutions that have a direct bearing on the more efficient and effective operation of the LED kit itself, affecting both safety while driving and the life of the product itself. A perfect example of this is the NTC sensor, which has recently started to appear as an integral part of the retrofit itself.

So what is this sensor and what is it responsible for?

With such small LED light sources as H7 bulbs, for example, it is important to add an element responsible for thermal coupling. When the bulb heats up above 90°C, the NTC sensor informs the current control system of the high operating temperature, which in turn begins to reduce the current so as to maintain the temperature at the same level. This stabilises the luminous flux, which has a positive effect on achieving a low drop of light per unit time.

Size...

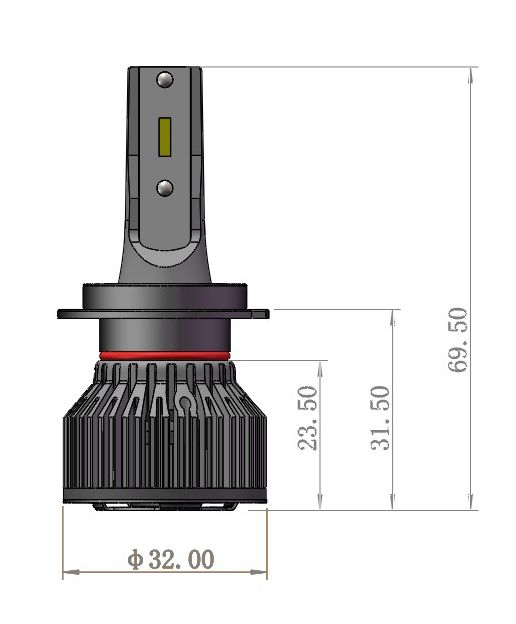

When selecting LED set category products, it is important to pay attention to their size. This has a direct impact on comfort during installation, as in many cars, unfortunately, headlamp space is quite limited. Buying retrofits that are too large may therefore present problems during installation, and in many cases this will be downright impossible.

M-TECH's LED retrofits are probably the smallest LED conversion kits for traditional lighting on the market. Their compact size means that they can be installed even where there is not much space. Thanks to the above-mentioned advantages, such as the FrontAir system and the light source in the form of the CSP1860 LED chip, it was possible to reduce the diameter of the heat sink. The reduction in size improves ergonomics during assembly and increases the air space between the cooling system and the walls of the mounting chamber. Counter-intuitively, this improves heat exchange and also offers new mounting possibilities.

Maintaining the design of the external Control Box...

Although it is possible to integrate the power supply in the bulb itself, as in the LSAL, LSF and LSG series, in the LSPRONG series we decided to retain the design of the external Control-Box. From the point of view of trouble-free operation as well as protection against possible interference that may occur in the car's power supply circuit, it became necessary to use appropriately sized filters as well as systems to absorb high energy surges.

Another factor was to maintain this separation due to thermal conditions and, more specifically, to ensure that the power supply system did not additionally heat the LED source, which would impair the lighting performance of the entire set-up.

To summarise...

All of M-TECH's series of LED retrofits are probably the most technologically advanced products of this type for the conversion of traditional lighting to LEDs available on the market. The use of a state-of-the-art solution responsible for the luminous flux in the form of a dedicated CSP 1860 LED chip, FrontAir cooling system, NTC sensor or maintenance of the external Contro Box design makes it difficult to look for similarly advanced solutions in this segment on the market. In addition, the reduced size/diameter of the heat sink and the removable flange means that even in the hard-to-reach and small spaces that we encounter in many headlamps, installation is not an obstacle/ an added value. All of this together results in a solution that provides more light for continuous operation and a low decrease in luminous flux per unit time (low drop). This could not have been achieved without meeting the previous requirements and without the work of our R&D team optimising the individual components of the design.i.

Bartłomiej Szternal

Product Manager