New LED SETs from M-TECH’s PRO NEXT GENERATION series

The LSPRO series, which has arrived from M-TECH, has changed the view of LED sets designed to convert traditional halogen lighting. Top-quality components such as branded LEDs, compact size and the ActiveAir cooling system have contributed to its success. As you know, despite the problems that the world has been facing due to the COVID-19 pandemic, among others, we have not stopped in our efforts to further develop the brand. Despite adversity, M-TECH continues to expand its product range in many segments of the automotive lighting market and to improve products that are already equipped with innovative solutions. The best evidence of this is the LSPRO Next Generation series.

Light source...

The light source is an extremely important, if not the most important, element we should pay attention to when purchasing an LED conversion kit for traditional automotive lighting. The LSPRO Next Generation uses the latest generation of the CSP1860 LED chip, which, thanks to its innovative design and the solutions used, allows up to 150% more light to be produced compared to the first generation. Contrary to appearances, the subject is not at all easy, as more flux from a smaller luminous area of the chip increases the operating temperature of the chip itself. The extraordinary luminous efficiency at such a small size was achieved thanks to the wire-free multi-point current distribution technology in a single chip, as well as the integration of 3 chips on a single substrate. This integration has resulted in a homogeneous rectangular light surface (with a shape and light distribution similar to that of a halogen filament), rather than the earlier generation, where the light sources were LEDs spaced apart. The new design results in a more homogeneous light, better coupling with headlights and lenses, and the absence of spots and shadows that appear on the street and occur with multiple individual LED chips (multi-chip). In addition, a specially selected common substrate integrates the thermal energy from 3 chips simultaneously and ensures better heat dissipation.

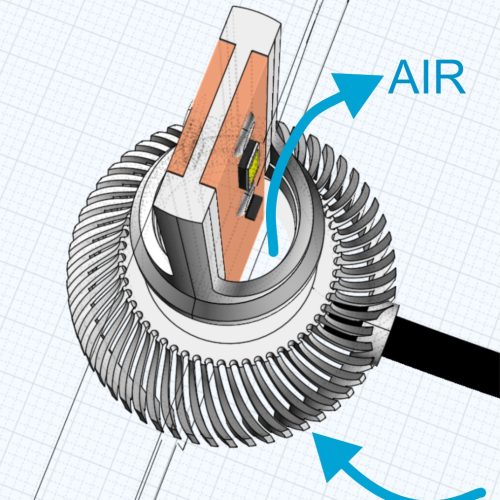

Cooling system...

The cooling system has been dramatically improved on the LSPRO Next Generation models. ActiveAir technology has been replaced by a much better solution. The addition of FrontAir technology, i.e. pushing air through the light stem chamber, forces air flow up to 20% on the outer part of the LED and cools the heated phosphor. This has a positive effect on the thermal stabilization of the chip and also forces air circulation in the reflector chamber itself. This has a direct impact on the service life and thus on road safety.

The use of an NTC sensor...

With such small LED light sources such as H7 bulbs, it is important to add thermal coupling. When the bulb heats up above 90°C, the NTC sensor informs the current control system of the high operating temperature, which in turn begins to reduce the current of the LED lamp so as to maintain the temperature at the same level. This stabilizes the temperature and, at the same time, the luminous flux. This also has a positive effect on achieving a low drop, i.e. a low drop in luminous flux in the time domain.

Size...

LSPRO was regarded as probably the smallest LED conversion kit for traditional lighting on the market. Its compact size meant that it could be installed even in hard-to-reach places. Going one step further, M-TECH is meeting the demands and expectations of consumers. Thanks to the aforementioned advantages, such as the FrontAir system and the light source in the form of the CSP 1860 LED chip, it was possible to reduce the diameter of the heat sink by 25% compared to the first generation. The reduction in size in the LSPRO Next Generation series improves ergonomics during assembly and also increases the air space between the cooling system and the walls of the mounting chamber. Counter-intuitively, this improves heat transfer and also offers new mounting possibilities.

Maintaining the design of the external Control Box...

Although it is possible to integrate the power supply circuit into the bulb itself, in the LSPRO series we nevertheless decided to maintain the design of the external Control-Box. From the point of view of trouble-free use, as well as protecting ourselves against possible interference that could occur in the car's power circuit, it became necessary to use appropriately sized filters, as well as systems to absorb high energy surges.

Another factor was to maintain this separation due to thermal conditions, specifically so that the power supply system would not additionally heat the LED source, which would degrade the lighting performance of the entire set-up.

In summary...

The newly designed LSPRO Next Generation series of retrofits is probably the most technologically advanced solution for converting traditional lighting to LED that is available on the market. The use of a state-of-the-art solution responsible for the luminous flux in the form of a dedicated CSP 1860 LED chip, FrontAir cooling system, NTC sensor or maintaining the design of the external Control Box makes it difficult to look for similarly advanced solutions in this segment on the market. In addition, the 25% reduction in the size of the heat sink means that, even in the inaccessible and small spaces encountered in many headlamps, installation is not a problem. All of this together means that this solution provides more light for continuous operation and a low drop in luminous flux per unit time (low drop). This could not have been achieved without meeting the previous requirements and without the work of our Research & Development team optimizing the individual components of the design.

Bartłomiej Szternal

Product Manager