Canbus system in LED retrofits.

Canbus system as a way of getting rid of the burnt-out bulb message.

Every motor vehicle, be it a motorbike or a car, is made up of many systems working together. These consist mainly of mechanical components, supported or controlled by electricity and electronics. It is known that with the degree of wear and tear, some parts of these systems may fail. Here we can distinguish between obvious and non-obvious failures. When I call obvious failures, I mean those whose symptoms cannot be overlooked by an average driver, e.g. "a flat tyre". As for the non-obvious failures, they may be minor malfunctions, which cannot be noticed, or simply a burnt-out bulb of the rear position light. Such a fault is easy to spot, but really, who of us goes around the car before every trip and checks the lights?

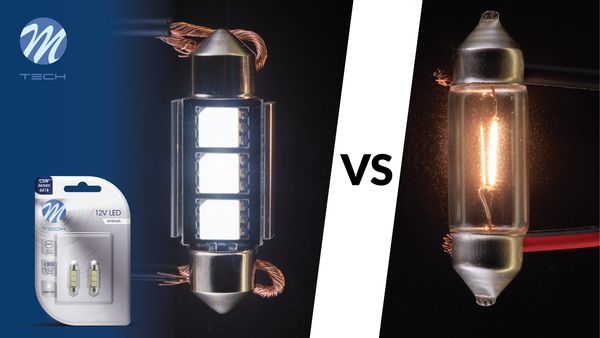

Non-obvious defects have a significant impact on the safety of road users. In order to prevent such faults, manufacturers have started to develop and install self-diagnostic systems so that the driver can be informed of a fault as soon as possible, before it has an adverse effect. Starting with oil pressure, charging voltage and brake fluid level indicators, the diagnostic systems became increasingly sophisticated and monitored other vehicle systems. One of the first bulb check computers was fitted to the BMW 7 Series E23 generation in the mid 1970s. It worked by simply checking electrical circuits. If the circuit was broken by a bulb burning out, an indicator light on the instrument panel illuminated. Over time, the systems evolved. As early as in the 1980s, the CAN (Controller Area Network) serial bus system appeared, which allowed two-way communication between modules of individual systems in the vehicle. The systems used today, especially in premium brands, are four-channel buses so developed that in addition to circuits, they also control the power and even resistance of bulbs, so as to detect the slightest exceedance of the assumed parameters and cut off power to a specific bulb, which the computer considers to be defective.

The message about faulty lighting often manifests itself in the form of a yellow light on the dashboard. This is a confusing phenomenon, because while the driver may associate this message with the previous replacement of selected bulbs in the vehicle with LED retrofits, they lose the ability to monitor the performance of the remaining bulbs in the vehicle. Manufacturers of retrofits for automotive lighting are therefore having a hard time tricking diagnostic systems into not displaying the message about burnt out bulbs. To do this, information is collected on the diagnostic methods the system subjects the bulbs to. These methods and parameters vary from vehicle manufacturer to vehicle manufacturer and from brand to brand. Based on the data collected, retrofit manufacturers create additional load systems to increase the energy consumption to a level equal to a conventional bulb. This system is called 'CAN bus' or 'Canbus', where the word 'bus' in this case does not mean bus, but a separate system that carries data and control signals in a computer system. The Canbus system in retrofits usually manifests itself in the form of an additional resistor package, which is integrated on the control board of the retrofit. Their power and resistance is selected strictly for a given retrofit, i.e. for the parameters of a traditional bulb that is replaced on the one hand, and for the type and number of light sources a given retrofit is equipped with on the other. Unfortunately, the level of complexity of modern diagnostic systems in vehicles does not allow to build a universal Canbus system for a given bulb, so that it would work in all cars. If it was to be, Canbus electronic system would physically overgrow the size of retrofits, in which it is used.

As you can see, there are many LED replacements for various types of incandescent bulbs in the offerings of leading automotive lighting retrofit manufacturers. The most extensive is usually the range of auxiliary and signal bulbs. Replacing position bulbs with LEDs is a very popular styling procedure among Polish drivers. Replacements for halogen headlight bulbs, which even in Western European countries gain residual road homologation, are also becoming increasingly popular. The multitude of products on offer is the result of the need to satisfy the needs of use and the imagination of consumers. Usually, a customer with the intention of buying LED retrofits already has a precise idea of their use and is looking for a product that meets the given criteria - bulb type, power, colour, direction of light, etc. Not all of these retrofits have an integrated canbus system, which is expensive to prepare and to manufacture. The need to use products with or without canbus comes directly from the car in which they are to be used. Users, who still want to use products without canbus, which are also often simply cheaper, but do not want to deal with the message about burned out bulb, can retrofit the installation with a set of additional resistors. On the market you can find universal resistors for parallel connection with parameters matched for a group of bulbs of similar power. There are also resistors dedicated for a given type of bulb, which are not only electrically matched, but even have a plug and socket compatible with a given bulb. However, users who choose to install LED retrofits in their turn signals may experience the effect of rapid bulb flashing, even though they have purchased Canbus products. This problem can be solved by replacing the indicator interrupter with one that is dedicated to LED bulbs.

The problem with a burnt-out bulb error does not only apply to LED retrofits, or other replacements that are simply less powerful than the nominal value. Similar problems may also be encountered by drivers who decide to improve their headlights by installing halogen bulbs, but with an increased wattage, such as H7 100W. Such a large difference in the power consumed by the bulb could be considered a fault or even a short circuit and the light control module could cut off power to the bulb.

Owners of cars manufactured in the last decade, especially premium brands, who primarily want to convert headlights from halogen to LED or xenon, often have problems with the Canbus and the resulting flashing and cutting of power to headlights armed with retrofits. A non-invasive procedure to change the software of the module in question can be a lifesaver. In some cases, a smartphone application that supports the service activities of a given brand and OBDII interface is sufficient to code the lighting diagnostics option in the vehicle. However, you have to reckon with the fact that until this option is switched on again, no messages about burnt-out bulbs will be delivered.

Author:

Dawid Bystroń

Product Manager of M-TECH